The metals service center industry in the United States has reached a market size of over 229 billion dollars. With that in mind, it is important to manage your slice of that industry well so you don’t miss out on opportunities.

Most sites now use metals service center software such as ERPs and ELDs to manage inventory, improve processes, and ultimately improve their bottom lines.

Yet, in spite of those systems, you may be finding that you still run into major roadblocks once materials leave your site due to poor fleet management. The potential fix? Complimenting your metals service center software with robust transportation management software (TMS).

Metals Service Center Software vs Transportation Management Software: The Basics

Before you can understand the ways that metals service center software (MSCS) and transportation management software (TMS) work together, it’s important to understand the basics of these two solutions.

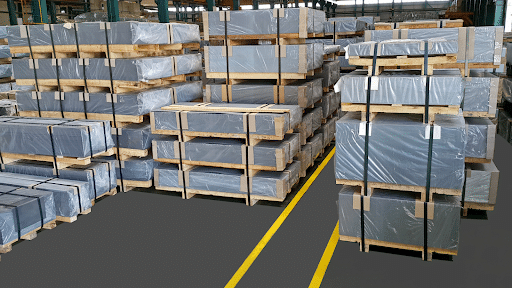

MSCS serves as a metals service center’s main ERP to manage inventory, help improve production processes, and provide risk management. Its end goal is to help improve bottom lines. This technology helps during the process of producing/storing materials/products to prepare for transport.

TMS, on the other hand, helps after the production/storage process. Its aim is actually managing the distribution of products (fleet of trucks to transport the metals from site to customer, etc.).

While having MSCS is beneficial, it doesn’t help prevent or solve accidents that can take place during the distribution process like TMS. Common issues include loading and traffic delays, customer demands for ETAs, and more. By pairing a TMS that integrates well with metals service center software or an ERP system, these sites can ensure that they maximize their margins during every step of their process from start to finish.

It turns out that pairing your metals service center software with a TMS can streamline the distribution of your site’s products and materials. Get our full breakdown on this new strategy to see why it’s worth looking into for your metals service center.

TMS Builds Your Process, Not Your “Tribal Knowledge”

Metals service centers are one part distributor and one part logistics company. Your business depends on getting trucks planned, products processed and pulled from inventory, loaded onto trucks, and out to customers when and where they want them.

It’s a huge job! And in spite of good metals service center software packages typically in use, that process of planning and managing your fleet often relies on extensive networks of knowledge that is distributed throughout your organization, depending primarily on people – individuals – to get the job done.

It’s not that people are bad. It’s just that they grow up, move on, retire, go on vacation, and sometimes forget details right when you need them! You can avoid this trap augmenting your metals service center software with a transportation management system that never goes on vacation, never quits, never gets recruited away by your competition.

We like to think in terms of systems and processes. Add a transportation management system to your metals service center software to build out your process and be less reliant on that tribal knowledge.

Make Distribution of Your Product More Efficient

When you purchase metals service center software, you ensure that your business has smoother internal processes. You increase your productivity and profitability, ensuring that your daily operations are more successful than they otherwise would be.

This gives your service center the boost that it needs to succeed during production and storage. However, it leaves workers in the dust after these processes are complete.

Integrating TMS into your day-to-day processes ensures that the products actually make it where they need to go post-production. It efficiently manages fleets of drivers that make deliveries so that customers can get their orders on time.

Ultimately, this ensures that your product gets to the location where it is needed efficiently. It prevents delays by ensuring that drivers take the shortest routes to their destination. This increases customer satisfaction because of faster shipping, which in turn boosts your reputation and drives repeat sales.

Provides a Better Experience For Drivers & Customers

Getting orders in a timely manner isn’t the only way that TMS and MSCS integration makes customers happy. Customer shipping demands are only increasing due to the growing metal wholesaling market.

To keep up with consumer expectations, you will need to provide frequent and specific shipping updates on products that they order. They should be able to see where their order is and when it will arrive. The information must be accurate if you want to retain your reputation as a service center that values customer satisfaction more than competitors do.

TMS can provide updates on when a particular shipment of products will arrive at the destination. Your production and distribution center will be able to access this information and provide the customer with updates. Customers also will be able to track shipments on the website and see estimated delivery dates and times.

Streamlines Communication With Drivers

In addition to streamlining transparency with your clients, you will also have the chance to increase distributor/driver communication.

Some metals service centers simply give the product to the driver and consider their jobs complete. The driver is then tasked with carrying out the delivery on their own.

By investing in TMS, there is increased accountability that leads to shared success. You can quickly communicate with drivers about any ongoing delays with deliveries or just check in on where they are at.

With TMS, drivers have the load and route information they need in the palm of their hand (via our app) showing them exactly when and where they need to be. Drivers also can receive real-time traffic data and turn-by-turn directions which further enhances distribution efficiency.

It also enables drivers to record proof of delivery in real time. On top of recording the time of day that a delivery is made, TMS can capture customer signatures electronically, and even “attach” photographs of the deliveries. Therefore, documenting both that the delivery was made as well as that products were free of damage at the time of drop off.

Provide Stronger Data to Back Business Decisions

Oftentimes, it can be difficult for companies to pinpoint exactly where a bottleneck is. By pairing your metals service center software with TMS, you can have automated “eyes” on every part of the process that will help provide more confidence and data behind important decisions.

When you have data-driven methods, you get better real-world results. This will ultimately lead to you implementing methods that get you the best possible returns on your investments.

Get High TMS ROI Today With Headlight Solutions

While you may think that diving into the world of TMS and metals service center software sounds easy, it is a fairly complex process. It’s critical that you have all available information before investing in a specific solution.Our experts are committed to helping you find this information so that you can have all the facts before you buy metals service center software.

We’re excited to discuss options that will help you with modern logistics management and freight booking. Request a demo of our web-based AI platform today to learn more.