Case

Studies

Introduction

“It’s been so refreshing to work with a company that caters to your needs like Headlight. The level of support has been outstanding and I’m not blowing smoke.”

Key facts

- Founded in 1945

- Headlight User Since: 2022

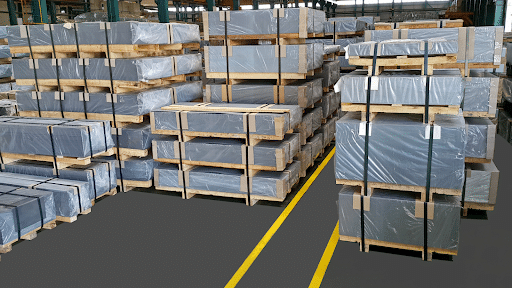

- Recycle 100 Million Pounds Of Steel And Other Metals Per Year

- Largest Stocking Distributor Of Carbon, Galvanized Steel, Stainless Steel And Aluminum Products

- Custom Metal Fabrication – Mechanical, Structural, Ornamental, Heavy Rolling Services

BEFORE HEADLIGHT

Before Headlight, Berman Brothers was using the typical software adopted across the industry to run their service center. After printing out paper tickets, hours and hours were spent mapping out the best routes using Google Maps and figuring out the best way to load a truck to get it out to each customer. The only information drivers had was a bunch of paper tickets stapled together. “Logistically, routing trucks was quite a nightmare” says Jesse Studio, Division Manager at Berman Brothers. “To route trucks, we had to rely on someone with really in-depth market knowledge. If they were out for the day, we were just kind of out in the wind. When we were using paper orders and something slipped through the cracks, the order wouldn’t get delivered and the customer would call us the next day wondering where their order was. Before Headlight, we dealt with some really big headaches.

AFTER HEADLIGHT

Since onboarding with Headlight, the operational process at Berman Brothers is much more steamlined and efficient. Today, trucks can be routed, loaded and out of the warehouse with load creation, driver assignment and notification, and route plans all automated. Additionally, orders are tracked in realtime and customers are automatically notified of delivery. Electronic paperwork means the accounting teams have orders invoices before the physical paperwork – which is slowly on its way out – has even returned to the warehouse. One of Jesse’s favorite features is being able to upload photos of completed shipments which the sales team references anytime a customer has a question about where, or when, or if a delivery has been made. According to Jesse Speegle, “Since we started using Headlight, our General Manager keeps calling it a ‘game changer.’ We’re seeing drivers coming around talking about how efficient it is. Our owner really loves Headlight’s tracking ability so he can see exactly where our drivers are throughout the day and how our customers are being serviced.” Headlight helps from a practical standpoint too – from printing less paper and proof of delivery to improved communications with customers and being able to send invoices in real time.

THE VALUE OF HEADLIGHT

According to Jesse Speegle, “A year in using Headlight has been a resounding success. It’s helped us operationally. It’s helped us with our customer service. It’s helped us be more efficient. It’s helped us communicate better with our fleet of drivers. It’s changed the way we handle that second half of the sales process – how to get our product to customers as efficiently as possible. To anyone considering adopting Headlight, dive in all the way. Go for it. It’s going to do nothing but help your business.”