Case

Studies

Introduction

ANCO Steel’s adoption of Headlight Freight is the classic story of successful process improvement: using technology to multiply the productivity of existing employees, eliminate and streamline redundant processes, and achieve direct cost savings.

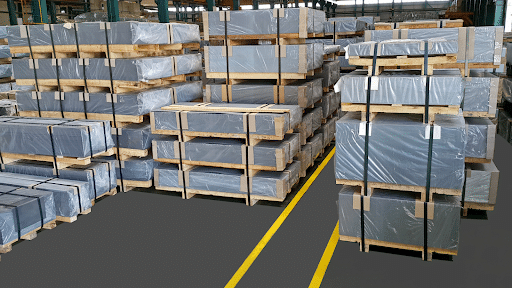

ANCO Steel is a family-owned metals distributor headquartered in Warrenville, Illinois, with four additional locations throughout the Midwest. Specializing in hot-rolled steel products, ANCO operates a large fleet of trucks and, additionally, hires significant quantities of 3rd-party, outsourced freight. In 2019, ANCO made the decision to adopt Headlight with the specific goal of improving 3rd-party freight costs and better capturing freight cost data. Headlight Solutions pairs boots-on-the-ground industry experience with modern, progressive AI software development to deliver optimized loads, routes, tracking and profits for distribution centers.

“Last month alone, we saved probably over 10 times the amount of money we spent on Headlight Freight.”

Key facts

- Private, Family-Owned

- Five Warehouse Locations

- ERP: Enmark Eniteo

- Headlight User Since: 2019

Before Headlight

Prior to implementing Headlight Freight, ANCO Steel interacted with their 3rd-party carriers in the traditional pen-and-paper manner, calling and emailing carriers in search of available freight capacity. But this entirely manual process limited employees’ reach. As the company’s Director of Operations, Barret Davids, describes, “The issue we had is that people are limited to the carriers that they know, so if someone was out

or not available, we lost the opportunity to get the best cost and performance.” Furthermore, the process of booking 3rd-party carriers was redundant and disorganized. Prior to using Headlight, “we weren’t able to capture how much we were spending on freight. We weren’t able to narrow it down by region, we weren’t able to narrow it down by person, and now we have all that data right at our fingertips.” Additionally, processing freight purchase orders and invoices was time-consuming and labor intensive. Prior to Headlight, we had to generate a freight purchase order for every load we covered,” says Mr. Davids. “Our accounting team would wait until the invoice came in, try to match it up, and see if the order was billed.”

Improvements

Now, using Headlight Freight, “we don’t have to spend the time creating freight purchase orders at all,” and even better, all the delivery confirmations are posted in real time and stored in Headlight for ANCO’s use: “the freight company can even upload the signed bill of lading so we have proof that everything was delivered. Our accounting team can go right in there and get the invoices processed right away.”

But what about freight costs? Davids is emphatic on this point: “within the last six months, ANCO has booked over a half-million dollars in freight [through Headlight Freight]. And doing so, we’ve managed to save 20%.” Last month alone, “we’ve saved probably over 10 times the amount of money we spent on Headlight Freight.”

The Results

Today, Headlight Freight has been absorbed seamlessly into the day-to-day operations of ANCO Steel. According to Mr. Davids, “we’re maximizing our time and getting everything covered immediately and capturing all that data right in Headlight Freight.” Cost savings are substantial – over 20% direct reduction in freight cost – and Headlight Freight has allowed ANCO to entirely eliminate the need for freight purchase orders. Furthermore, the system has reduced the time to process invoices, a direct impact on working capital and DSO. How best to sum it all up? Mr. Davids takes care of that point too: “Headlight Freight has been amazing for us.”